|

|

#1

|

|||

|

|||

|

Is there any company doing L.S.D.'s for the S12?

Mines a Mk2 i think (1988).... |

|

#2

|

||||

|

||||

|

no but you can get a ATB from quaife

__________________

http://insightbookingsolutions.co.uk |

|

#3

|

||||

|

||||

|

And if you don't have £600 spare for a Quaife then you can use an S13 LSD with some other bits, for very little money.

|

|

#4

|

|||

|

|||

|

600?.....

.....Thats over double what i paid for the car - S13 it is then. .....Thats over double what i paid for the car - S13 it is then.If anyone who has used and S13 diff could post up some picks of it, plus extra parts i need - i would really appreciate it. Thanks |

|

#5

|

||||

|

||||

|

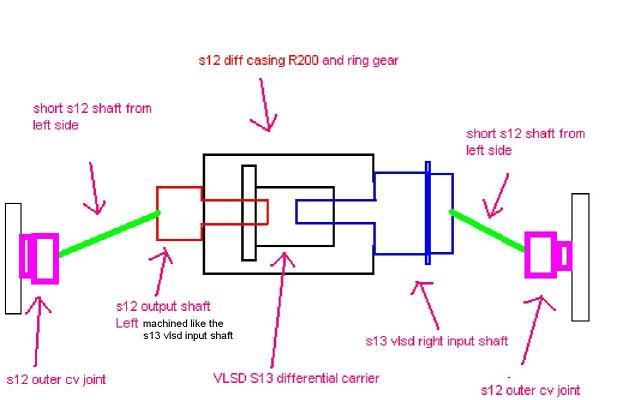

You need the S13 diff, 2 left hand silvia shafts and one S13 inner 6 bolt CV joint housing and related driver side inner shaft....

Fully strip the S13 LSD, and removing the ring gear from it. Throw ring gear, case, shims etc in the bin Then strip the S12 diff, and rebuild it with the S13 inner diff unit. ie bolt the S12 ring gear to the S13 unit. Then the shafts need some work. You use the short S12 shaft on the driver side with the S13 inner joint/inner On the short side (passenger side) you can use the standard short shaft but you have to remachine so its like the S13 shaft.

|

|

#6

|

||||

|

||||

|

Cant the left output shaft be used from the s13/s14 diff?

__________________

86 Silvia Grand Prix - under reconstructio |

|

#7

|

||||

|

||||

|

No because it makes the shaft too long, and it full compresses up the cv joints and it even pushes the swing arm outwards

|

|

#8

|

||||

|

||||

|

Quote:

, now thats bit of a problem) , now thats bit of a problem)

__________________

86 Silvia Grand Prix - under reconstructio |

|

#9

|

||||

|

||||

|

I thought I might add that in the Vlsd the V stands for viscous. Viscous diffs are basically a single open diff with some friction plates that heat up a fluid which then engages the other half but only if it gets hot enough. This system works well if used for an extended period of time or if warmed up before use (eg small burnout) but generally, when driving around normally it wont do anything if you try to drift straight up. So it is a cheap alternative to a proper lsd but its like anything you get what you pay for.

|

|

#10

|

||||

|

||||

|

i cant see how this set up would be reliable as you are using 2 different types of joint on the same drive shaft. CV which isn't supposed to move and a lobro joint which is designed to move. i cant see the CV joint lasting very long

__________________

http://insightbookingsolutions.co.uk |

|

|

|